Building a startup is a masterclass in resourcefulness. True cost efficiency isn't just about cutting expenses; it's about strategic spending that fuels growth. In an environment where every dollar counts, implementing effective cost reduction strategies can be the difference between burning out and breaking through. This guide moves beyond basic bootstrapping advice, offering nine powerful, actionable frameworks that successful businesses use to optimize operations, slash waste, and build a more resilient financial foundation.

We'll dissect tactics ranging from Lean Manufacturing and Process Automation to Strategic Sourcing and Value Engineering. Each item is designed to be a practical blueprint, not a theoretical concept. You will learn how to identify operational inefficiencies, consolidate technology stacks, and optimize your workforce for maximum impact. This approach ensures that cost savings directly contribute to a stronger, more competitive business model.

Moreover, a core principle of lean operation is building what customers actually need, thereby avoiding wasted development cycles. This starts with proper market validation. A tool like ProblemSifter is invaluable here, as it scans communities like Reddit to find unfiltered user problems. By identifying genuine pain points before you build, you prevent the most significant cost of all: creating a product nobody wants to pay for.

1. Lean Manufacturing

Lean manufacturing is a systematic methodology for minimizing waste within a production system without sacrificing productivity. It’s one of the most effective cost reduction strategies for businesses with physical products, focusing on eliminating non-value-adding activities. This approach, pioneered by Toyota, identifies and removes "waste" across all operational processes, from raw material sourcing to final delivery.

How Lean Manufacturing Drives Cost Reduction

The core principle is to create more value for customers with fewer resources. Lean manufacturing categorizes waste into eight distinct types, often remembered by the acronym TIMWOODS: Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects, and Skills (unused talent). By systematically targeting these areas, companies can drastically reduce operational overhead. For instance, Boeing reduced the assembly time for its 737 aircraft by 50% by applying lean principles, directly cutting labor and facility costs.

Actionable Implementation Steps

Implementing lean manufacturing requires a cultural shift towards continuous improvement.

- Start Small: Begin with a pilot program in a single department to demonstrate value and refine your approach before a company-wide rollout.

- Invest in Training: Your team is the most critical asset. Provide comprehensive training on lean principles and tools to ensure everyone understands their role in waste reduction.

- Visualize Your Workflow: Use visual management tools like Kanban boards to make processes, bottlenecks, and progress transparent and easily understood by everyone.

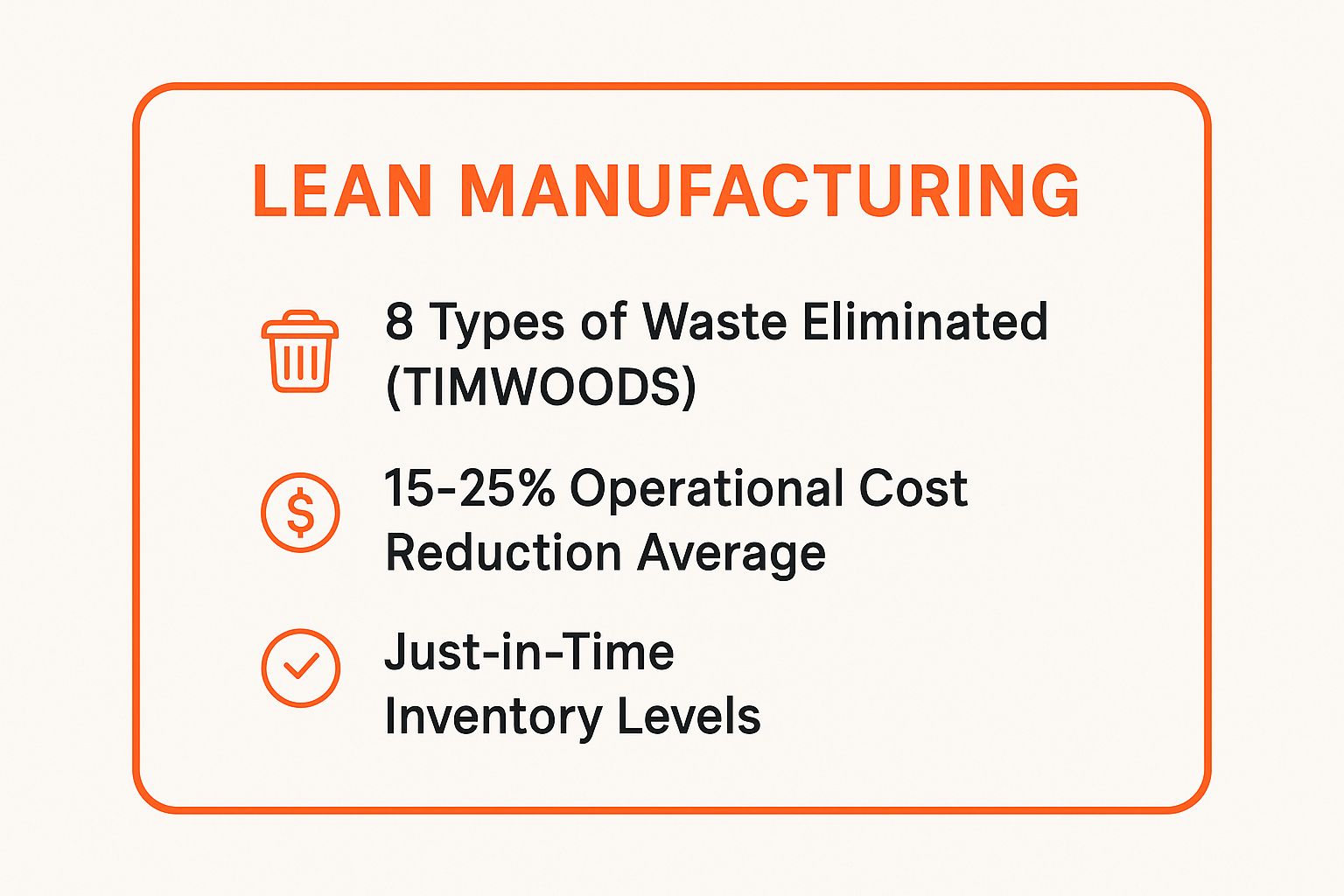

The following infographic highlights the core areas of focus and the potential impact of adopting a lean methodology.

As the data shows, the methodology's strength lies in its clear framework for identifying waste and its proven ability to lower costs through just-in-time inventory management. This systematic approach ensures resources are allocated precisely where they add value, maximizing efficiency.

2. Process Automation

Process automation involves using technology to execute recurring tasks or processes that would otherwise require manual effort. As one of the most impactful cost reduction strategies, it leverages tools like robotic process automation (RPA), artificial intelligence, and machine learning to streamline operations, minimize human error, and significantly lower labor expenses. This approach frees up employees to focus on higher-value activities that require critical thinking and creativity.

How Process Automation Drives Cost Reduction

The primary benefit is the direct reduction of operational costs by replacing expensive, time-consuming manual labor with efficient, automated workflows. This not only accelerates processes but also improves accuracy, eliminating the costs associated with fixing human errors. For example, JPMorgan Chase automated its contract analysis, reducing 360,000 hours of manual legal work to mere seconds. Similarly, American Express automated its invoice processing, achieving an 80% cost reduction in that function by minimizing manual data entry and validation.

Actionable Implementation Steps

Successful automation requires careful planning and a strategic, phased approach.

- Start with Rule-Based Tasks: Begin by automating simple, repetitive, and rule-based processes like data entry or report generation. This ensures early wins and builds momentum for more complex projects.

- Map Your Processes: Before implementing any tool, thoroughly map the existing workflow to identify inefficiencies, bottlenecks, and the precise steps that can be automated. This blueprint is critical for success.

- Prioritize Integration: Choose automation tools that integrate seamlessly with your existing systems (CRM, ERP, etc.). A well-integrated platform prevents data silos and maximizes the return on your investment.

By automating the right processes, startups can operate with a leaner team, scale more efficiently, and redirect capital toward growth initiatives. The key is to view automation not just as a cost-cutting tool but as a strategic enabler for operational excellence and competitive advantage.

3. Strategic Sourcing

Strategic sourcing is a comprehensive procurement practice that continuously re-evaluates and improves a company's purchasing activities to maximize value. It’s one of the most impactful cost reduction strategies for businesses of all sizes, moving beyond simple price negotiation to a holistic analysis of market conditions, supplier capabilities, and total cost of ownership. This approach transforms procurement from a transactional function into a strategic asset.

How Strategic Sourcing Drives Cost Reduction

The core principle of strategic sourcing is to develop a proactive, long-term relationship with suppliers that aligns with the company's goals. Instead of just chasing the lowest price, it focuses on the total value, including quality, reliability, and innovation. For example, General Motors achieved over $1 billion in annual savings by consolidating its supplier base and building deeper partnerships. This method reduces administrative overhead, secures better terms, and mitigates supply chain risks, leading to significant and sustainable cost savings.

Actionable Implementation Steps

Implementing strategic sourcing requires a data-driven and collaborative approach.

- Conduct a Comprehensive Spend Analysis: Start by gathering and analyzing data on what your company buys, from whom, and for how much. Identifying these patterns is the foundation for any effective sourcing strategy.

- Build Cross-Functional Teams: Involve stakeholders from finance, operations, and quality control. This ensures that sourcing decisions support broader business objectives beyond just the initial purchase price. For a structured approach to this collaboration, you can learn more about problem-solving frameworks that facilitate cross-departmental initiatives.

- Focus on Total Cost of Ownership (TCO): Evaluate suppliers based on more than just their price tag. Consider costs related to logistics, quality, maintenance, and potential downtime to understand the true long-term financial impact.

4. Energy Efficiency Optimization

Energy efficiency optimization is a systematic approach to reducing energy consumption across an organization's operations, directly cutting utility costs and environmental impact. It's one of the most impactful cost reduction strategies because energy is a universal, and often significant, operational expense. This strategy involves a mix of technological upgrades, process improvements, and behavioral changes to eliminate energy waste without compromising productivity or comfort.

How Energy Efficiency Drives Cost Reduction

The core goal is to perform the same or better work using less energy. This is achieved by identifying and rectifying inefficiencies in systems like HVAC, lighting, and equipment. By focusing on high-consumption areas, businesses can achieve substantial savings. For example, Walmart launched a comprehensive energy program that included upgrading to LED lighting and installing more efficient refrigeration systems, saving the company an estimated $1 billion annually. Similarly, Google's focus on data center efficiency has reduced its energy costs by 40%, showcasing the strategy's power at scale.

Actionable Implementation Steps

Implementing an energy efficiency plan requires a data-driven and phased approach.

- Start with an Energy Audit: Hire a professional or use an internal team to conduct a thorough audit. This will identify the biggest areas of energy waste and highlight the highest-impact opportunities for reduction.

- Prioritize Quick Wins: Begin with low-cost, high-return initiatives like switching to LED lighting or installing programmable thermostats. These actions often have short payback periods and demonstrate the value of the program.

- Engage Your Team: Create awareness programs to encourage energy-saving behaviors, such as turning off lights and equipment when not in use. Incentivizing participation can drive a culture of conservation.

The following infographic highlights the key areas where energy efficiency measures can be applied for maximum financial and environmental benefit.

As the data suggests, a combination of technological upgrades and behavioral adjustments delivers the most significant savings. By continuously monitoring consumption with energy management systems, businesses can ensure sustained cost reduction and operational resilience.

5. Outsourcing Non-Core Functions

Outsourcing non-core functions is the strategic practice of contracting external organizations to handle business operations that are not central to a company's primary value proposition. This is one of the most direct cost reduction strategies for startups and established firms alike, allowing them to focus resources on their core competencies. By delegating tasks like IT, HR, or customer support, companies can access specialized expertise and economies of scale they couldn't achieve internally.

How Outsourcing Drives Cost Reduction

The fundamental benefit comes from converting fixed labor costs into variable operational expenses. Instead of maintaining a full-time, in-house team for a peripheral function, you pay a specialized provider, often at a lower cost due to their scale and efficiency. This model minimizes recruitment expenses, training overhead, and benefits packages. For example, Procter & Gamble outsourced its IT operations to HP, achieving a 10% cost reduction while gaining access to world-class technology infrastructure.

Actionable Implementation Steps

Successful outsourcing requires careful planning and vendor management, not just a hand-off.

- Define Your Core: Clearly identify which functions are absolutely essential to your unique value and which are support activities. Only outsource the latter.

- Conduct Thorough Due Diligence: Vet potential partners rigorously. Look at their track record, client testimonials, and financial stability. Don't just choose the cheapest option.

- Establish Clear SLAs: Create Service Level Agreements (SLAs) with specific, measurable performance metrics. These contracts are crucial for holding your vendor accountable and ensuring quality.

The key to this strategy is leveraging external expertise to handle necessary but non-critical tasks. This frees up capital and internal talent to focus on innovation and growth, directly impacting the bottom line.

6. Inventory Optimization

Inventory optimization is a strategic approach to maintaining the ideal quantity of stock, balancing carrying costs against the risks of stockouts. It's one of the most impactful cost reduction strategies for businesses managing physical or digital goods, as it directly frees up working capital. This methodology uses data analytics and demand forecasting to ensure product availability without tying up excessive funds in unsold items.

How Inventory Optimization Drives Cost Reduction

The core goal is to minimize the total costs associated with inventory, including storage, insurance, obsolescence, and the opportunity cost of capital. By aligning stock levels with actual customer demand, companies avoid both overstocking (which inflates carrying costs) and understocking (which leads to lost sales and customer dissatisfaction). For example, Zara’s fast-fashion model, which relies on rapid inventory turnover and demand sensing, allows it to minimize warehousing costs and avoid deep markdowns on unsold clothing.

Actionable Implementation Steps

Effective inventory optimization relies on a data-driven, systematic approach.

- Implement ABC Analysis: Categorize your inventory into A, B, and C groups. Focus your most rigorous control efforts on 'A' items, which represent the highest value, to get the biggest return on your optimization efforts.

- Invest in Forecasting Tools: Use modern demand sensing technologies or inventory management software to create more accurate forecasts. This moves you from reactive ordering to proactive, data-informed stock management.

- Establish Clear Policies: Define key performance metrics like inventory turnover rate, carrying costs, and stock-to-sales ratios. Monitor these metrics regularly to track progress and make necessary adjustments to your strategy.

7. Workforce Optimization

Workforce optimization is a comprehensive strategy for maximizing workforce productivity and efficiency while controlling labor costs. This approach goes beyond simple headcount reduction, focusing instead on strategic planning, skill development, performance management, and optimal resource allocation. It represents one of the most impactful cost reduction strategies as it balances financial savings with long-term employee engagement and retention.

How Workforce Optimization Drives Cost Reduction

The core principle is to align your human capital with business objectives, ensuring you have the right people with the right skills in the right roles at the right time. This strategy minimizes waste related to idle time, skill gaps, and employee turnover. For example, UPS uses its ORION system to optimize driver routes, saving an estimated $400 million annually through reduced fuel and labor hours. Similarly, Starbucks uses workforce analytics to adjust store staffing based on peak hours and customer traffic, effectively reducing labor costs by 8% without compromising service quality.

Actionable Implementation Steps

Implementing workforce optimization requires a data-driven and people-centric approach to human resources.

- Utilize Workforce Analytics: Use HR data to identify productivity trends, skill gaps, and opportunities for improvement. This data provides the foundation for all strategic staffing and training decisions.

- Implement Cross-Training Programs: Develop a flexible workforce by training employees in multiple roles. This versatility allows you to adapt to changing demands without needing to hire new staff, reducing recruitment and onboarding costs.

- Establish Clear Performance Metrics: Define clear key performance indicators (KPIs) and implement a regular feedback system. Setting up a structured process, like a quarterly review template, ensures alignment and continuous improvement.

- Consider Flexible Work Arrangements: Offer remote or hybrid options to reduce overhead costs associated with office space, utilities, and other facilities.

This methodology's strength lies in its ability to unlock hidden efficiencies within your team, ensuring that your largest expense, labor, generates the highest possible return on investment.

8. Technology Consolidation

Technology consolidation is a strategic initiative to reduce IT overhead by standardizing, integrating, and eliminating redundant software and hardware. This approach streamlines a company's technology landscape, a critical goal for growing startups managing an expanding suite of tools. It is one of the most direct cost reduction strategies for tackling subscription fatigue and simplifying maintenance, ultimately improving operational efficiency.

How Technology Consolidation Drives Cost Reduction

The core benefit comes from reducing complexity and waste in the IT stack. By auditing all applications and systems, businesses can identify overlapping functionalities, unused licenses, and inefficient workflows. Eliminating these redundancies cuts direct software licensing costs and reduces the hidden expenses of training, support, and integration. For instance, Bank of America famously consolidated over 13,000 applications down to 3,500, a move that saved the company billions and drastically simplified its operations.

Actionable Implementation Steps

A successful consolidation project requires careful planning and stakeholder alignment.

- Conduct a Portfolio Assessment: Start by creating a complete inventory of all software, applications, and infrastructure. Analyze usage data, costs, and business criticality for each item.

- Prioritize Based on Impact: Focus first on consolidating systems with high costs, low utilization, or significant functional overlap. Prioritize the quick wins to build momentum and demonstrate value.

- Engage Business Stakeholders: Involve department heads and key users early in the process. Their input is crucial for understanding how technology supports business processes and ensuring a smooth transition.

This strategic approach ensures that technology investments are lean and directly support business objectives, preventing the accumulation of "tech debt" that can hinder scalability and profitability. It shifts the focus from managing a multitude of disconnected tools to creating a cohesive, efficient, and cost-effective digital ecosystem.

9. Value Engineering

Value engineering is a systematic methodology for improving the "value" of goods, products, or services by examining function. Value is defined as the ratio of function to cost, meaning it can be increased by either improving the function or reducing the cost. This is one of the more analytical cost reduction strategies, focusing on achieving required performance at the lowest possible lifecycle cost without sacrificing functionality, quality, or reliability.

How Value Engineering Drives Cost Reduction

The core of value engineering is function analysis, which distinguishes it from other cost-cutting methods. Instead of simply trimming expenses, it asks, "What does this component do?" and "Is there a cheaper way to achieve the same function?" This structured, creative problem-solving approach leads to significant savings by identifying unnecessary costs. For example, by applying value engineering, NASA reduced the cost of certain Space Shuttle components by 30%, and Caterpillar achieved an incredible $2.8 billion in cumulative savings over 15 years by optimizing product functions.

Actionable Implementation Steps

Implementing value engineering requires a cross-functional team and a structured approach to innovation.

- Focus on Function: During brainstorming, concentrate on the purpose of a product or process, not its current form. This opens the door to completely new, more cost-effective solutions.

- Assemble a Diverse Team: Bring together experts from design, engineering, marketing, and finance. Diverse perspectives are crucial for identifying innovative ways to improve value.

- Pilot and Test: Before committing to a full-scale change, implement the proposed improvements on a smaller scale. A pilot program helps validate the solution and calculate potential savings accurately.

This function-first mindset is a powerful part of a robust innovation management process, ensuring that every decision is tied to delivering core value efficiently. By systematically questioning every aspect of a product's design and production, teams can uncover hidden inefficiencies and unlock substantial cost savings.

Cost Reduction Strategies Comparison

| Item | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

| Lean Manufacturing | High - requires cultural change and training | Significant upfront investment and ongoing maintenance | 15-25% cost reduction; improved quality and engagement | Manufacturing focused on waste elimination | Reduces waste, improves quality, faster time-to-market |

| Process Automation | High - tech integration and maintenance | High initial technology investment | 25-50% labor cost reduction; error elimination and faster processing | Repetitive tasks, data-intensive workflows | Increases speed, accuracy, frees strategic workforces |

| Strategic Sourcing | Moderate to high - requires deep market and spend analysis | Significant time and analytical resources | 10-30% procurement cost savings; risk reduction | Procurement and supplier management | Cost savings, supplier performance improvement |

| Energy Efficiency Optimization | Moderate - involves tech upgrades and monitoring | High capital investments and ongoing monitoring | 20-30% energy cost reduction; sustainability benefits | Facilities aiming to reduce energy consumption | Cost savings, sustainability, tax incentives |

| Outsourcing Non-Core Functions | Moderate - selection and contract management | Moderate with vendor management needs | 20-40% operational cost reduction; access to expertise | Support functions outside core competencies | Cost reduction, access to expertise, scalability |

| Inventory Optimization | High - requires forecasting and system upgrades | Sophisticated forecasting and IT systems | 15-35% inventory carrying cost reduction; better availability | Inventory-heavy businesses needing balance | Cash flow improvement, reduced obsolescence |

| Workforce Optimization | High - complex planning and training | Significant investment in analytics and training | 15-25% labor cost reduction; productivity and flexibility gains | Labor-intensive industries with variable demand | Productivity improvement, flexibility, skill development |

| Technology Consolidation | High - involves IT system rationalization | High upfront integration and migration costs | 20-40% IT cost reduction; simplified management | Organizations with redundant IT systems | Cost savings, reduced complexity, enhanced security |

| Value Engineering | Moderate to high - thorough functional analysis | Skilled facilitators and cross-functional teams | 10-25% cost reduction while maintaining quality | Product design and manufacturing optimization | Cost reduction, innovation, improved design |

The Ultimate Cost Reduction Strategy: Build What People Need

Throughout this guide, we've explored a comprehensive suite of cost reduction strategies designed to fortify your startup's financial foundation. From adopting lean manufacturing principles and embracing process automation to optimizing your workforce and consolidating technology, each tactic offers a powerful lever for improving operational efficiency. Strategic sourcing, value engineering, and inventory optimization are not just about cutting expenses; they are about building a more resilient, agile, and competitive business.

However, the most profound and impactful cost reduction strategy transcends operational tweaks. It is the fundamental act of building a product that people genuinely need and are willing to pay for. The financial waste generated by developing un-wanted features, marketing to the wrong audience, or solving a non-existent problem can dwarf any operational inefficiency. The cost of a failed product is the ultimate expense, consuming not only capital but also invaluable time and team morale.

The Proactive Approach to Cost Management

This is where a proactive, validation-first mindset becomes your greatest asset. Instead of retroactively trimming budgets, you can eliminate the source of the biggest potential losses from day one. For indie hackers, solopreneurs, and early-stage founders, this means embedding market validation into the very core of your ideation process. By focusing on real, documented user pain points, you move from speculation to data-driven conviction.

This approach transforms your entire operational model:

- Marketing costs decrease because you know exactly who your target customers are and where to find them.

- Development waste is minimized as you build features that directly address validated user needs, avoiding a bloated and unnecessary product backlog.

- Sales cycles shorten because your solution resonates instantly with the problems your prospects are actively trying to solve.

From Ideation to Validation: The Modern Toolkit

Fortunately, modern tools have made this validation process more accessible than ever. Tapping into online communities like Reddit provides a direct, unfiltered view into the frustrations and desires of niche audiences. This is the new frontier for identifying startup opportunities.

Tools like ProblemSifter are purpose-built for this, turning raw community discussions into a pipeline of actionable startup ideas. Unlike other tools, ProblemSifter doesn’t just suggest ideas—it connects you to the exact Reddit users asking for them. It identifies the real, unfiltered problems on Reddit and provides not just the idea, but the original post and the Reddit usernames expressing the pain point. For just $49, you can get lifetime access to a curated list of real startup problems people are discussing in a specific community. With no subscriptions or hidden fees, this small, upfront investment is one of the most powerful cost reduction strategies you can deploy, preventing the catastrophic expense of building in the dark.

Ready to stop guessing and start building what customers actually want? Explore ProblemSifter today to find your next startup idea backed by real user pain points. For a small one-time investment, you can prevent the massive cost of building the wrong product and connect directly with your first potential customers.